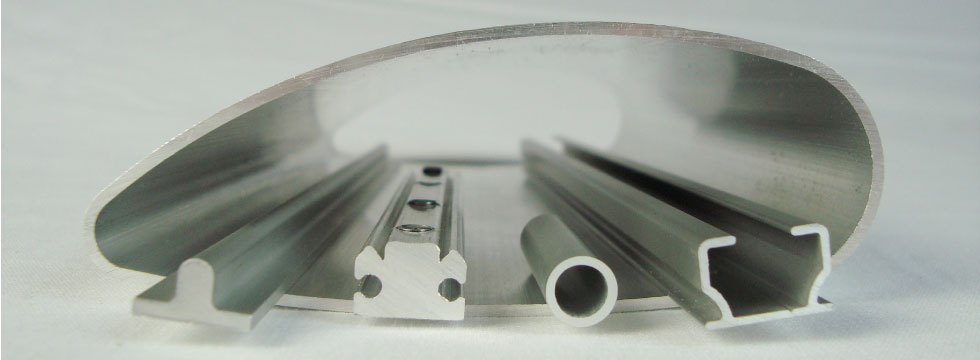

This special material is often not recognizable at first sight, especially when it comes to aluminium components that fit harmoniously into the overall picture. Such components are, for instance, aluminium profiles. They are used in various areas: for example in mechanical engineering, furniture construction, construction technology or in the solar industry.

Particularly in the last-mentioned context, mostly aluminium profiles that have been developed according to the customer’s requirements are used instead of standard profiles.

Here a partner is needed who can refer to a long experience in the field of profile and extrusion technology – like Aluso GmbH.

The way to an individual aluminium profile

Creating an individually planned aluminium profile is usually not exclusively about performing milling work. Aluminium is a material that can be processed in a variety of ways, which is why many different processing steps are possible.

Aluminium profiles can be sawn in order to achieve the required lengths, as well as they can be provided with drill-holes to adapt them exactly to the intended application. Furthermore, there is the possibility of applying various surface treatments – from painting and foiling to powder coating to anodizing, grinding and polishing.

drilling aluminium

Drilling makes it possible to provide aluminium with precise indentations. A drill-hole is usually characterized by a round shape and can either deepen the processed material at a single spot or even break through it. To plan a drilling, at least information has to be available about how deep the deepening should be and what diameter it should have. In this way, the holes can be precisely adapted to what they are intended for. If you compare drilling and milling, you will notice that milling is usually more complex in its processing. However, drilling aluminium can be an important work step in the production of individually planned aluminium profiles, while various drilling tools make it possible, to make the intended specifications.

When could drilling be required?

Drilling in aluminium profiles is often already necesssary when it comes to relatively simple components. For example with protruding profiles which are intended to protect individual stair steps or other objects and which must offer a fixture to attach them. Compensation and adaption profiles, which are required for example when laying floors, lead to a similar situation. They help to create a height adjustment and thus eliminate tripping hazards. Transition profiles also often need drill-holes.

Refining aluminium profiles

The mechanical processing of aluminum profiles is an essential step towards the desired end product. However, drill-holes, millings and other specifications per se often do not lead to a profile that is capable of mastering all challenges. Profiles, such as those mentioned above, which are used on floors, are a good and simple example here.

Angle properties and design of the angle legs

The most common angle profiles have a 90-degree angle and can therefore be used, for example, to frame or connect two components that are at right angles to one another. Right-angled profiles are not the only angle profiles that are important in industry. Sometimes acute-angled profiles are required to perform specific tasks. The design of the legs can vary as well.

Angle profiles made of aluminium

Basically, angle profiles can be made of a wide variety of materials. However, due to its special material properties, aluminum plays an outstanding role here. Aluminum does not only convince by its low weight, it is also strong at the same time, but it can also be easily adapted and processed. Precise cuts, drilling and many other mechanical processes are thus possible. Angle profiles made of aluminum, which are still visible after their installation, are also visually attractive and can therefore significantly increase the end product’s value. In the production of angle profiles Aluminum is not only used in several mechanical processes, but also in various surface finishes. This ensures that the angle profiles produced are always ideally adapted to their area of application. In addition to profiles that are produced in the shape of an angle, there are numerous other profile shapes. A comparable simple profile shape is similar to the capital letter “T”. While the longer element of such a profile can be used, for example, to close the cavity between two other components, the horizontal element in this case rests flat on the components of the same height. In this way, for instance, a useful cover can be achieved by using a T-profile, which can be fixed in various ways.

Aluso has been dedicated to aluminum profile technology for many years and has thus become an experienced and reliable partner for industry. At the same time, the company always keeps a firm eye on the future and has recognized that aluminum profiles have also become indispensable in new, innovative industrial sectors.

Aluso is the competent contact for all customers in the furniture industry, construction industry, automotive and mechanical engineering technology.